As one of the world's important crops, cassava also plays a key role in the animal feed processing industry. The purpose of this paper is to discuss the issues of cassava feed production that investors are more concerned about: the characteristics of cassava raw materials, cassava processing feed production methods and related feed processing machines. Through this article, we hope to answer your questions about how you use cassava for animal feed and provide you with practical guidance and references.

How to Make Animal Feed Using Cassava Pellet Machinery?

How to Make Animal Feed Using Cassava Pellet Machinery?

Essential Cassava Animal Feed Formula: Simple Recipe for Optimal Nutrition

Before exploring how to make animal feed using cassava, let's delve into the properties of cassava. After understanding the characteristics of cassava, I will provide a sample recipe for your reference.

Leveraging Cassava Nutrient Composition for Animal Feed Production

Cassava is a commonly used ingredient, and its characteristics affect the nutritional value and cost of animal feeds. Only with a clear understanding of the nutritional value of cassava, can you design an efficient and cost-effective feed formulation.

- 84% Carbohydrates and 10% Protein

Cassava is rich in carbohydrates and a small amount of protein, which is one of the important nutrients required for animal growth. Its high starch content makes it a good source of energy.

- 94% Digestibility Increases Feed Efficiency 15%

After processing, cassava can be quickly digested and absorbed by animals, which helps to improve their feed utilization.

- 95% Durability Index Makes Feeds Easier to Form

The raw material itself is highly viscous, and when processed into pellets by animal feed processing machines, it can be easily bonded and moulded, and is not easily broken.

- 280 Million Tons of Production with Lower Costs

Cassava production is widely distributed in tropical and subtropical regions, with a large planting area and high yield, so the price of cassava is relatively stable and lower.

Example Cassava Feed Formulations for Different Animals

When making animal feeds, cassava (tapioca) is used as one of the basic ingredients that need to be formulated according to the needs of different animals. Below are some simple sample recipes:

| For Poultry Feed | For Cattle Feed | For Sheep/ Goats Feed | For Fish Feed |

|---|---|---|---|

| 50% Cassava | 40% Cassava | 50% Cassava Chips | 60% Cassava |

| 20% Soybean Meal | 30% Wheat Bran | 20% Alfalfa Hay | 20% Soybean Meal |

| 20% Cornmeal | 20% Corn Silage | 15% Soybean Meal | 10% Fishmeal |

| 5% Fish Meal | 5% Molasses | 10% Rice Bran | 5% Wheat Bran |

| 5% Vitamin and Mineral Premix | 5% Salt | 5% Salt | 5% Vitamin and Mineral Premix |

Application of Cassava Feed Pellet:

- Cassava for Poultry Feed: chicken, duck, goose, etc.

- Cassava for Livestock Feed:cattle, sheep, pigs, rabbits, etc.

- Cassava for Fish Feed:(freshwater fish) carp, crucian carp, grass carp, etc.

Methods for Converting Cassava to Animal Feed: Manufacturing Process

How do You Convert Cassava to Animal Feed?

How do You Convert Cassava to Animal Feed?

Fresh cassava, cassava residues (wastes) and cassava pulp are all different products of cassava processing. They may use similar processes in the preparation of animal cassava feeds, but there are some differences. Below are the feed production process flows for these three raw materials:

- Raw Material Preparation Stage:

Cassava: Select mature cassava, remove the outer skin, and then slice or chop it into pieces.

Cassava Residue (Waste): Collect the residue left after cassava processing.

Cassava Pulp: A pulpy substance obtained by grinding, soaking, and pressing fresh cassava.

- Pretreatment (Optional):

Cassava and Cassava Residue: Soaking is a common pre-treatment method that helps to remove cyanide compounds from them.

Cassava Pulp: Cassava pulp is typically pre-treated and may therefore not require additional soaking treatment.

- Processing Treatment:

Heat treatment or Fermentation: Processing the pre-treated raw materials through methods such as boiling or steaming. High temperatures aid in breaking down cyanide compounds in cassava, ensuring product safety. Additionally, fermentation can be used to remove cyanide compounds from cassava residue.

Drying: Drying of wet cassava raw material to reduce its moisture content (Suitable moisture: 10 ~12%). Dried raw materials are easier to process into powder or granules. (Link to Feed Drying Equipment>>)

Crushing and Mixing: Grind the dried raw materials into a powdered form. And then, thoroughly blend cassava powder with other feed ingredients according to specific ratios. (Know more about Animal Feed Processing Equipment>>)

- Pelleting Process:

The mixed feed ingredients are fed into the animal feed pellet mill for pelletization, producing animal cassava feed pellets.

Explained above is the way to use cassava roots as animalfeed. Apart from that, cassava leaves and stems can also be used as fodder. If you need it, click below for a free consultation!

Cassava Feed Pellet Making Machine For Sale

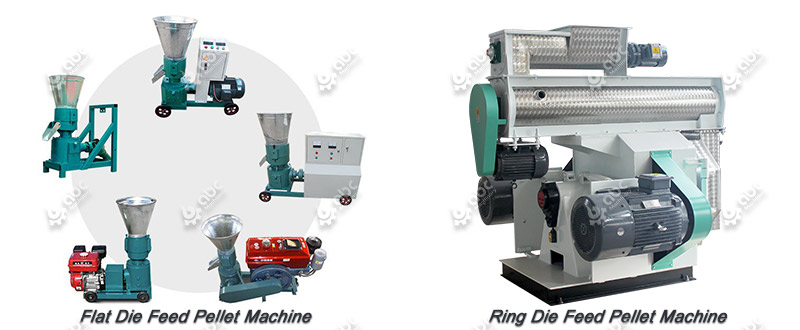

Cassava feed pellet machine can be divided into small feed pellet processing machine and large feed pellet processing machine.

Best Animal Feed Pellet Making Mills For Sale

Best Animal Feed Pellet Making Mills For Sale

Small feed pellet mill, also known as flat die pellet mill, is better suited for smaller farms, ranches and individual homes. These machines are usually smaller in size and relatively low in price, making them more suitable for small-scale production and homemade use.

Large feed pellet mill refers to ring die feed pellet mill, which is usually applicable to larger scale feed manufacturers. Ring die feed pellet machines have a higher production capacity and are able to meet the needs of high-volume production. These large feed processing machines usually have more powerful power systems and higher production efficiency, and are able to handle more raw materials and produce high quality cassava pellet feed for animals.

Choosing Cassava Animal Feed Manufacturing Line for Your Business Plan

The cassava pellet feed production process relies on efficient animal feed production lines. Choosing the right animal feed production line is crucial for cassava pellet feed production. The following are the key points to note when choosing a feed pellet production line:

- The production scale and expected output need to be considered to determine the capacity and configuration of the animal feed pellet production line.

- Animal feed processing equipment should adapt to the characteristics of cassava pellets, such as professional cassava pellet feed making machines and drying equipment, to ensure product quality and production efficiency.

- The flexibility of the animal feed processing line should adapt to the market demand and product changes. For example, the best animal feed manufacturing line should quickly adjust the proportion of ingredients and production process.

- The degree of automation of the feed pellet processing line also needs to be considered. A high degree of automation of the animal feed making plant can improve production efficiency and quality stability, reduce labour costs.

Best Small Animal Feed Processing Machine Set for Sale

Best Small Animal Feed Processing Machine Set for Sale

ABC Machinery's Animal Feed Pellet Plant Project for Sale

ABC Machinery's Animal Feed Pellet Plant Project for Sale

Only comprehensive consideration of the configuration and performance of the feed production line, choose the right feed processing machine to ensure the smooth production of cassava pellet feed. In this process, you feed mill investors can best find engineering experts to consult the advice and evaluation. If you have any questions or needs, you can directly contact us for free help.