Project Name: 10 Ton per hour Cassava Dregs Pellet Production Line

Raw Materials: Cassava (Tapioca) Dregs, Wastes, Residues

Application: Pelletizing cassava wastes for convenient storage or making animal feed pellets

Yield: 8-12ton per hour (8~12TPH)

Make Cassava Pellets

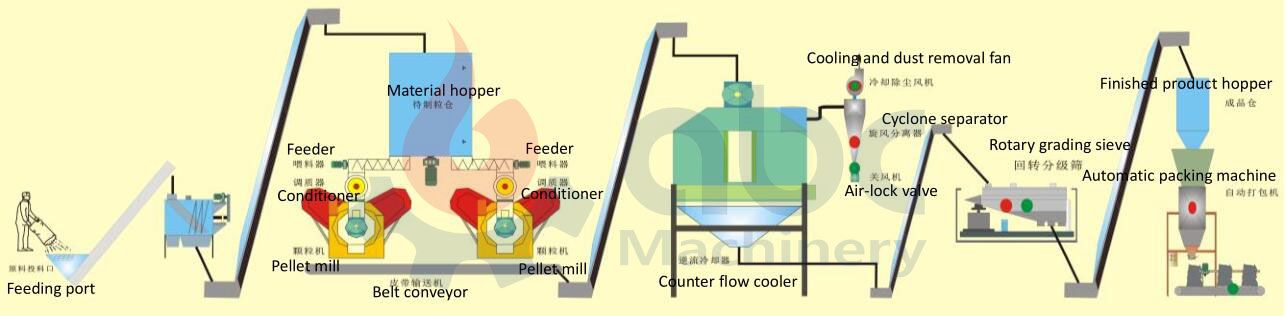

Cassava Dregs Pellet Making Process

10 Ton per Hour Pellet Making Project Plan for Cassava Residues / Wastes

The temperature of cooled pellets: No more than 5 degrees of the room temperature

Pellet moisture content: <13% (materials moisture content<13%)

Pellet forming rate: ﹥95%

Requirement to the steam boiler: 0.4~0.6MPa 0.4-0.6t/h(provide for themselves)

Power requirement: 380V 50Hz three phase four lines about 273Kw(equipment capacity)

Requirement to the compressed air: 0.6MPa 5.5kw (provide for themselves)

External dimension: L 20m W 5m H 4.8m

Cassava Pellet Making Machine

Don't hesitate to get in touch with us if you are planning to start your own business of cassava pellets processing, or feel interested to know cost and other details of this project plan. (info@bestpelletplant.com)

Equipment List of 10TPH Cassava Pellet Production

| No. | Name | Type | Number | Power (kw) | Remark |

|---|---|---|---|---|---|

| 01 | Tipping pit | 1 | 0 | Field fabrication | |

| 02 | Screw conveyor | TLSS25 | 1 | 3.0 | Whole sealing auger cylinder, it can convey materials at a big dip angle. |

| 03 | Drum type pre-cleaner | SCY125 | 1 | 0.75 | Get rid of the large impurities in the materials. |

| 04 | Belt conveyor | DJ80 | 1 | 7.50 | The big dip angle sidewall type belt conveyor, the belt width is 800mm. |

| 05 | Material hopper | 1 | 0.55 | Round cylinder, with arch breaker. | |

| 06 | Material levelling device | 4 | 0 | Damped rotation type level indicator | |

| 07 | Ring die feed pellet mill | KMPM 45B | 2 | 231 | Stainless steel feeder;single-layer stainless steel conditioner, conditioning shaft, paddle,opening access port, stainless steel door cover, feeding pipe;double-motor belt driving,the driving is stable,maintenance cost is low;with stainless steel ring die. |

| 08 | Belt conveyor | DT60 | 1 | 2.2 | Collect the end product of two set of pellet mills. |

| 09 | Belt conveyor | DJ80 | 1 | 7.50 | The big dip angle sidewall type belt conveyor, the belt width is 800mm. |

| 10 | Counter flow cooler | NKSL21×21 | 1 | 1.9 | Octagon cooling hopper,without cooling blind angle. |

| 11 | Fan | 4-72-8C | 1 | 22 | With distributing device, the blast capacity is 17463-22435m³/h, the full pressure is 2478-2390Pa. |

| 12 | Cyclone separator | 55-1,D=1600 | 1 | 0 | it realizes the solid-gas separation, after purify and cool the waste gas, it is equipped with the second bucket. |

| 13 | Air-lock valve | TGFY2.8L | 1 | 0.75 | Air locking and discharging device. |

| 14 | Air net pipeline | 1 | 0 | ||

| 15 | Belt conveyor | DJ80 | 1 | 2.2 | The big dip angle sidewall type belt conveyor, the belt width is 800mm. |

| 16 | Rotary grading screen | SFJH130×2C | 1 | 2.20 | |

| 17 | Belt conveyor | DJ80 | 1 | 7.50 | The big dip angle sidewall type belt conveyor, the belt width is 800mm. |

| 18 | End product hopper | 1 | 0 | ||

| 19 | Automatic packing machine | LCS50 | 1 | 2.25 | Including measurement scale, Needle seam machine, belt conveyor. |

| 20 | Electric control system | 1 | 0 | It adopts 3c authentication East China electric appliance. | |

| 21 | Wire and cable trough | 1 | 0 | The customer can purchase according the site situation. | |

| 22 | Steel for installation | 1 | 0 | The customer can purchase according the site situation. | |

| 23 | Hardware for installation | 1 | 0 | ||

| 24 | Installation and debugging | 1 | 0 | Computed separately | |

| Total |

292 Kw |

Including tax but not including freight |

Installation condition(if it needs to be installed by ABC Machinery, you should make the following preparation):

- The demander should prepare the plant pit and install the boiler and power before the equipments are installed.

- The demander should supply interpreter, mechanic and electrician each for one (they should take charge of the production and maintenance), 3-4 auxiliary workers are needed.

- Supply electric welding machine, acetylene oxygen welding electrode and 3T chain block each for one (specification is in the tool list).

- The supplier should send 1-2 technicians to the demander plant, and they should take charge of the installation, debugging and training of the operating staff. The demander should be responsible for the round trip air tickets, certificate fee and the expenses for board and lodging during the installation.

- The installation and debugging period is about 30 days, the fee if USD 100/person/day. If there is delay because of the demander problems, for example: insufficient preparation or the coordination degree of the auxiliary works is not high, etc. The exceeding part should be added USD 50/person/day.

The equipment making period: within 45 after receiving the down payment.

Installation and debugging time: 25 days after the demander finishes the preparation.

The electric control cabinet is paced by the wooden box, while other equipments are packed without package. The transportation of the whole set of equipment need two 40 feet containers.