Animal feed pellets are prepared by putting excessive pressure on the raw material in the feed pellet machine which converts them into cylindrically shaped pellets. These pellets are all-in-one which means they have all the essential nutrients such as minerals, vitamins, proteins, fats, etc. that poultry and livestock need to grow big and healthy. Farmers feed this healthy feed to their cattle, chickens, sheep, and pigs to get more meat and milk in return. (Read more: Small Cattle Feed Plant Cost >>)

Make Animal Feed Pellets for Cattle Chickens

- The suitable size for each kind of animal: poultry feed 1-3mm, livestock feed 3-5mm; cattle and sheep feed 6-10mm; fish feed 0.4-2mm.

- The most suitable raw materials used for feed pelleting process include wheat bran, maize straw, corn fiber, soybean meal, grass, molasses, peanut seedlings, etc.

Ring Die Feed Pellet Mill for Commercial Feed Plant Setup

Our BPM Series animal feed pellet mills are designed for commercial feed pellet plant for poultry or livestock. The parts of this ring die feed pellet mill contacting pelletizing materials are mostly stainless steel. You can also customize the feed pellet mill with stainless steel on the whole body. (Related project: Animal Feed Manufacturing Plant Setup in Uzbekistan >>)

BPM Series Animal Feed Pellet Mill for Sales

| Model | BPM25 | BPM32 | BPM35 | BPM42 | BPM45 |

|---|---|---|---|---|---|

| Power of Main Motor | 22kw | 22kw×2 | 30kw×2 | 45kw×2 | 55kw×2 |

| Capacity(t/h) | 1~2 | 2~5 | 3~7 | 4~10 | 6~15 |

| Inner Diameter of Ring Die(mm) | 250 | 320 | 350 | 400 | 450 |

| Power of Feeder(kw) | 0.75 | 0.75 | 0.75 | 1.5 | 1.5 |

| Power of Conditioner(kw) | 1.1 | 2.2 | 2.2 | 4 | 4 |

| Size(mm) | 1750×650×1750 | 1900×1800×1650 | 2100×2000×1850 | 2200×2000×2150 | 2300×2350×2150 |

| Weight(kg) | 800 | 2000 | 2400 | 2900 | 3500 |

BPM 35 and the above types of animal feed pellet mill adopts double motor driving, high strength, SPB narrow type, V-belt driving, stable and reliable running, low noise. What's more! This series of ring die commercial feed mill equipment is equipped with the Danfoss frequency converter, the feeding is accurate and reliable. This series animal feed pellet mill is CE and ISO9000 certificated.

Main Spare Parts - Ring Die and Press Roller for Animal Feed Pellet Mill

Chicken/Cattle Feed Pellet Mill Factory [Project Display]

Ring die feed pellet mill is widely adopted to setup medium or large scale feed pellet processing plant for poultry, cattle or fish. Now, starting feed manufacturing business by setting up a commercial feed pellet project has been a hot investment in many regions since the increasing and huge demand for animal feed pellets. (Read more: Poultry Feed Plant Project Report >>)

If you are now considering to entering animal feed processing industry, just take actions quickly. It is definitely a profitable investment. If there are any questions about the feed pellet plant setup cost, machine specifications and others, just contact us for more technical information!

Animal Feed Pellet Mill Manufacturer - ABC Machinery

Set up commercial poultry/cattle feed mill plant – factory price ring die feed pellet for animal feed manufacturing: buy ring die feed pellet mill from animal feed pellet machine manufacturer or supplier at factory price, get FREE technical instruction of animal feed pellet production process and business plan to set up commercial feed pellet mill project in Philippines, Uzbekistan, Lithuania, Nigeria, Tanzania, etc., at low cost.

Advantages of BPM Series Feed Pellet Mill for Sale

- There is a plate in the feeder of feed pellet mill, by controlling the pull rod, it can discharge the wrong matched material out of the pelletizing system directly not passing through the rind die chamber.

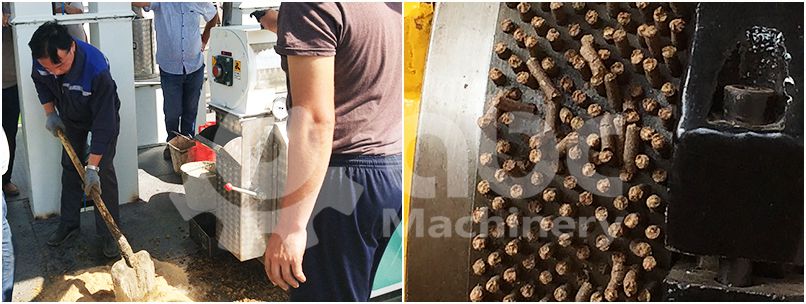

Feeder (left) and Pelletizing Assembly (right)

- Pellet diameter is usually 1.5-12mm. So it can produce suitable feed pellets for different animals, including chickens, cattle, goat/sheep, pig, fish, etc.. It has good feed production effect, and the pellet density is uniform.

Ring Die Feed Pellet Machine Pelletizing

- There are three drainage scrapers, which can make the materials distribute evenly preventing the block.

- One-piece main shaft can realize adding oil without stopping the machine, which greatly improves the production efficiency.

Main Shaft of Ring Die Animal Feed Pellet Mill

- Quick-release hoop ring die shortens the changing time and improves the production efficiency.

- The roller assembly has eccentric shaft. It can prolong the roller service life time by adjusting the clearance and taking full use of roller skin.

High Quality Press Rollers of Animal Feed Mill

- Ring die hole diameter, compression ratio can be customized. The pelletizing chamber has cutter, it can adjust the pellet length easily.

- There is a preformed opening to add water/steam, you can choose to use. The conditioner number can be added or reduced according to the need.

- There are three lubricating parts, the operation is convenient and concise.

Lubricating Design of Animal Feed Mill

- The belt cover has a lot of small holes, and the electrical machine has heat dissipation device to produce the pelletizing room chamber which guarantees the normal running of the inside machine.

Poultry Feed Pellet Mill at Factory Price

ABC Machinery, as a leading feed pellet mill supplier in China, we never stop optimizing our solutions of animal feed pellet manufacturing plant for our customers to help them reduce investment cost and improve the production efficiency. In addition, we have experienced and professional oversea installation team. Just contact us to get more information!

-

I'm Indonesia, I'm looking for ring die pellet machine for shrimp feed production, pellet diameter 2 mm and lenght 2 mm.

Its capacity at least 400 kg/h for feed.

-

Thanks for interesting in our equipment.

Regarding the pelelt press with ring die for shrimp, I want to know do you have the existed pellet plant already to match the pellet press with ring die?

Also, you make this pellet with floating or not? -

Dear

Thanks for your answer. It is really good copy of CPM Pellet Mill.

I need to manufacturing sinking pellets. - We want to know what kind of raw materials you plan to process? If there is no extra requests on the ring die, we will use the ring die that it was speical for shrimp.

-

Our budget is limited for now. Our target price is no more than USD 3500 CIF surabaya. Our raw material is corn, fish meal (almost 50%) , fish oil,

soybean, and wheat flour. All of them are crushed by disk mill to be powder before mixing and pelletziing. - Email attachment is our proposal of the shrimp feed pellets production line for your reference.

-

Need information on poultry feed mill (small and medium scale) please.

Thank you. - Our company can offer animal feed manufacturing solutions for both small and large production, capacity from 60KG/H to 16 ton /h, so would you tell us what is your capacity requirement for the material, so that we give you cataloge soon. By the way, what is your raw material? and 4mm pellet needed by you?