If you are planning to run a chicken feed processing plant and want to get some tips to make your feed pellet processing factory more effecient, or your very first poultry feed mill is about to put into production and need some get started quickly, ABC Machinery can always help you!

Processing Chicken Feed Pellet

ABC Machinery is one of the chicken feed pellet processing machinery manufacturer and supplier, offering high quality equipment and professional service. Here is an article about chicken feed processing. Welcome to contact us for more information for free!

Pelletized Chicken Feed Processing Plant

Small Chicken Feed Processing Unit for 1-2 ton/h Production Line

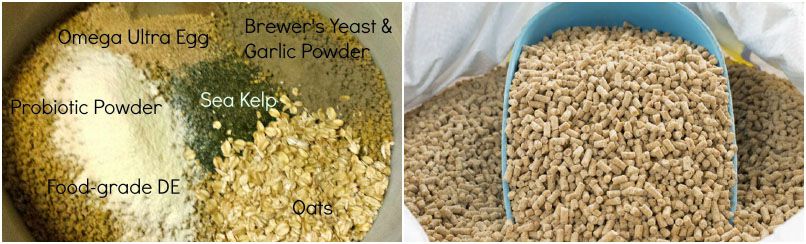

The primary reason to prefer pelletized feed is, it ensure the adequate intake of nutrients for the chick. These days, peletted feeds are the most preferred feeds for the poultry animals. While pelletized feed production, all the ingredients are grounded and mixed together in a machine to form a specific feed requirement and desired combination of nutrients. (HOT SALE Small Poultry Feed Plant >>)

Pelletized feed is the best feed choice of the chickens!

Why Choose Feed Pellets Rather Than Mash Feed?

When compared with using mash feed, the followings are some advantages of feeding your chicken wit feed pellets produced by chicken feed pellet machine :

- Nutritional Composition: It consists of the proper and required proportion of the nutrients and ensures that the chicken receives the desired nutrients in adequate amount.

- Improve Performance: Ensuring balanced diet of the chicken, it improves the bird performance and lessens the wastage of feed.

- Feed Safety: As the process included high temperature, it ensures, no bacteria gets pass on to the chicken through the feed. The food is sterilized in the process.

Main Grain Used in Manufacturing Feed for Poultry

Making Chicken Feed Pellets

Grain is the main raw material for the ingerdients of animal feed pellets including poultry feed and cattle feed. For corn feed mill plant, corn is included as one of the ingredients in the feed. In most feed pellet plant around the world, corn is a common ingredient in the chicken feed, Australia being an exception. In Australia, fewer areas have the suitable conditions to grow corn; hence the corn feeds are produced really less in Australia. Corn fed chickens tends to have a slight yellow skin color. Due to the less availability of corn, it is usually replaced by wheat and sorghum in the chicken feeds in Australia. Grains used in the chicken feeds largely depend on its local availability. Maybe you are also interested in fish feed production and the related machines.(Recent News: 5 ton/h Feed Processing Plant for Cow Feed>>)

Make a Proper Chicken Feed Processing Plant

During the growing days, chickens require proper nutrition and that's the reason there should be a proper chicken feed plans for them. Now talking about the chicken feed composition , it differs in the egg-producing chickens (layer) and meat producing chickens (broiler). The feed should contain a properly balanced nutritional ratio that will prevent slow growth and leg problems in the chicken. The feed production team needs to analyze the requirements of the chicken to prepare a proper feed for them.(Read more: animal feed manufacturing business plan pdf>>)

Setup a Small Chicken Feed Processing Mill

Making high quality chicken feed from scratch is never an easy task. Though a proper feed is prepared from 85% -90% of cereal grains, it cannot be completely made of grains. The feed must include soybean meal, salt and concentrated vitamins and minerals as well. The different nutritional needs and the levels of growth have a direct effect on the chicken feed production. (Related Post: 1 ton/h Small Chicken Feed Plant Project Report >>)

Video of Processinig Chicken Feed in Feed Pellet Plant

Here is the working video of our chicken feed processing plant. Please don't hesitate to contact us for more information!

Realize Low Cost and High Efficiency of A Chicken Feed Plant

Reducing costs and improving efficiency has always been one of the effective measures for chicken feed companies to gain competitive advantage, especially in the relatively fierce market environment, to effectively save production costs, improve their own efficiency and achieve stable and sustainable development. It is especially important to choose a professional feed plant manufacturer or supplier, because from process advice, project design, factory building and equipment installation will affect the future cost reduction and efficiency improvement of the whole production line. (Read More: 100 ton/h Large Scale Poultry Feed Pellet Mill Business Plan >>)

For investors, the first consideration upfront is how to reduce upfront investment, which includes not only factory building construction cost and equipment procurement cost, but also the future long-term equipment maintenance cost. The "cost reduction and efficiency improvement" in the early stage of starting chicken feed factory construction needs to consider. (Related article: small poultry feed mill machinery>>)

- Investors should do a good job of the local chicken feed market research before building a feed plant, to make sure the most popular feed type, to avoid blind investment, and choose a more promising feed varieties according to the local market situation.

- Reasonably determine the architectural structure of the chicken feed pellet production factory. Due to the high requirements of feed production on the plant environment, concrete structure has been the main choice of feed plant way.

-

Choose a professional and reliable manufacturer to setup the production process and complete sets of the chicken feed making machine that meet your own conditions.

Firstly, the design of the production process directly affects the subsequent equipment procurement and long-term production benefits of the feed production enterprise. Process flow needs scientific design and reasonable planning. Secondly, the selection of production machinery is also a key factor in relation to the quality of finished feed products and the level of production costs.

In a word, the selection process should be "efficient and low consumption" and "improve the efficiency of man and machine" as the construction principle, to avoid equipment and production requirements do not match. When you plan to build chicken feed processing factory, feel free to contact us!

Successful Projects Setup around the World

| Projects Name | Project Location |

|---|---|

| 1~2 TPH Poultry Feed Processing Plant | Uganda |

| 1TPH Chicken Feed Plant | Thailand |

| 2TPH Cow Feed Making Machine Line | Kuwait |

Tips for Broiler Chicken Feed Processing Design

With the increase in demand of the poultry feed consumption, chicken feed production too has become a very important aspect to be focused on. Now coming to the different kind of feeds:

Nutritional Requirements of Growing Broiler Chicken Feed

Requirement of any of the following nutrient is relative to the other nutrients there are few factors that need to be considered before expressing the need of a certain nutrient. Quantity of one nutrient depends on the quantity of the other. For example, the percentage of calcium, phosphorus and sodium are interdependent.

- Proteins: In the dietary requirements of chicken soyabean meal, canola meal and meat and bone meal constitute of the protein majorly. The daily crude protein intake is always kept least in the feed, for it provides an adequate amount of essential amino acids in the chicken diet.

- Amino Acids: The growth rate of the chicken depends on the percentage of Amino acid in the chicken feed. An adequate amount of amino acid is required to ensure rapid growth of the chicken and for a successful, meat chicken feed program.

- Minerals: The quantity of minerals in the feed not only depends on the requirement, but it majorly depends on the bioavailability of the mineral sources. For different sources the concentration of minerals differs. For example, there is a difference in the bioavailability of zinc in zinc sulphate and zinc oxide.

- Vitamins: It is said that the vitamin requirements of chicken reduces with the growing age. Though there's no concrete argument to prove it. Vegetable oils or animal fats are the optional ingredients to be included in the diet to provide additional energy.

Composition of Typical Broiler Feed

The composition of the chicken feed varies with the varied growing stages of the chicken. The feed producers usually have a 3 stage feeding program, depending on which the feed changes as the chicken grow. It basically has the: Starter feed, Grower feed and the Finisher feed. Some of them have also introduced a withdrawal feed just before the harvest. Compared to all the other feeds, the finisher feed has the lowest composition of protein and higher in energy.