With the wood pellet market set to grow in the coming years, investing in the wood pellet production project is an excellent addition to any portfolio. Searching a reasonable and cost-effective wood pellet plant construction for your business plan? Look no further than our project report for wood pellet production construction. (Related article: how to start a wood pellet production business>>)

Start Business with Wood Pellet Plant Contrusction Design

With over a decade of experience in building wood pellet making projects, we are a trusted supplier and manufacturer, providing not only the wood pellet making equipment at factory prices, but the comprehensive engineering design for wood pellet production plant. If you have any inquiries, please don't hesitate to reach out to us.

Successful Wood Pellet Plant Construction Setup Report

Speaking of the production and construction of wood pellet plants, it's worth mentioning our successful pellet processing projects that have been established in various countries worldwide. Below are some examples of pellet production projects completed for our clients, which may serve as a useful reference. (Related article: small wood pellet production plant setup>>)

As a specialized wood pellet machine supplier and manufacturer, our team of engineers and technicians strictly follows our clients' requirements and actual production processes to design and construct the wood pellet production facilities, including factory layout, production process design, and equipment selection. If you have any question about making wood pellets for profit, invest in wood pellet making machine industry, or starting wood pellet production plant consitruction, we are always here for you with the latest price list and low cost. Welcome to contact us for free!

Key Factors to Start Wood Pellet Plant Construction for Your Business Plan

The construction for a wood pellet plant involves the process of designing, building, and equipping a facility that produces wood pellets for use as a renewable energy source. And this construction process includes site selection, setup design and layout, equipment and machinery selection and installation etc. (Read more: biomass pellet project cost>>)

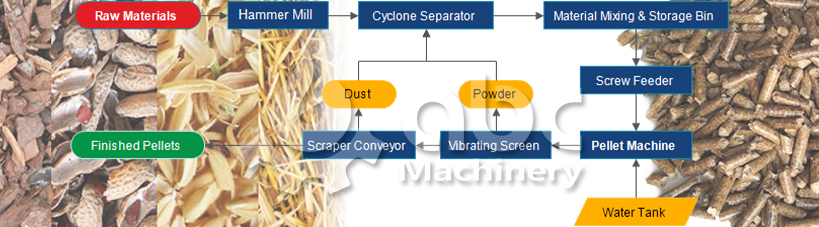

Typical Wood Pellet Production Rpocess As Business

Factory Site Selection for A Wood Pellet Production Plant

The site selection process is a critical aspect of establishing a successful wood pellet production plant. Several factors must be considered when selecting a site:

- The ideal location for a wood pellet processing factory is typically near a source of raw materials to reduce costs and increasing efficiency for your wood pellet production business.

- The site should be accessible to transportation infrastructure, such as highways or railways, to facilitate the distribution of finished products.

- Environmental regulations must also be taken into account when selecting a site for a wood pellet production factory. Air quality control, waste management, and water conservation are all essential considerations.

- The plant must comply with local, state, or federal regulations to ensure the sustainability and environmental impact of the wood pellet processing facility.

Design and Layout Considerations For Wood Pellet Production Facilities

Designing and laying out a wood pellet production facility is a critical step in ensuring efficient and effective operation. The layout must take into account the flow of raw materials, equipment placement, and worker safety. It's important to minimize the distance between key production areas and ensure smooth transitions between different stages of the production process. The facility should also be designed to minimize energy use and reduce waste. Careful planning and attention to detail during the design and layout phase can lead to significant cost savings and increased productivity over the life of the wood pellet production facility.

For more information about wood pellet plant construction setup, you can coantact us at no cost.

Equipment and Machinery Selection for Wood Pellet Plant

Selecting the right equipment and machinery is crucial to the success of a wood pellet plant. The equipment must be capable of handling the volume and variety of raw materials required for efficient and high-quality pellet production. In addition to the pellet machine, some auxiliary equipment for large wood pellet rpoduction is also required in order to produce better quality wood pellets, which includes wood chipper, hammer mills, dryers, coolers, pellets bagging machine. It's important to choose equipment that is energy-efficient and able to produce high-quality pellets with minimal waste. Careful consideration should also be given to the size and layout of the equipment to ensure optimal use of space and worker safety. With the right equipment and machinery, a wood pellet plant can achieve maximum efficiency and profitability.

Quality Control and Testing Methods for Wood Pellet Production Business

Ensuring high-quality wood pellets is essential for the success of a wood pellet plant. Quality control measures and testing methods should be established to monitor the moisture content, ash content, and calorific value of the pellets. Raw materials should be inspected and tested to ensure they meet established standards. Regular sampling and testing should be conducted throughout the production process to identify any quality issues and make adjustments as necessary. Careful quality control can prevent production of subpar pellets and ensure customer satisfaction. With thorough testing and quality control measures, a wood pellet plant can produce consistently high-quality pellets and establish a strong reputation in the industry.