There are many types of wood pelleting machines each having its special instructions, way of using, advantages and disadvantages. If you are looking for the most professional and cheap wood pellet making machines or planning to start an automatic wood pellet plant with low cost and investment, then you are in the right place. Below we are going to introduce our HOT SELL Small Pellet Mill Machine as well as the common types of fuel pellets, the pelletizing process and many other things related to wood pellet manufacturing. (Successful Projects: 4 TPH Automatic Wood Pellet Plant in Morocco>>)

Wood Pelleting Machine for Small Pellet Mill Plant

ABC Machinery is one of the leading companies in wood pelleting machines and biomass pellet plants. We are good at designing and manufacturing various capacities of wood pellet machines and offering turnkey solutions of pellet mill plants for both small and large scale wood pellet production. Whenever you feel interested in establishing a wood pellet mill or want more about our wood pelletizing projects, please feel free to contact us! We will offer warm-hearted service to you!

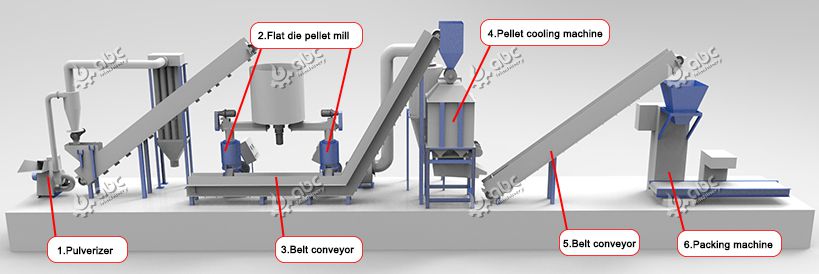

Small Wood Pelleting Business Factory Layout and Equipment Setup

Our mini pellet plant has been HOT Sale in recent years for those who want to start wood pelleting business or as a trial operation. The general technological process of wood pelleting machine is:

Necessary Machines for Wood Pellet Mill Plant Process

| Process | Equipment |

|---|---|

| Raw Materials collection (wood and biomass wastes) | Truck is OK |

| Crushing (less than 3mm) | Crusher, hammer mill |

| Drying (moisture content within 12-15%) | Dryer |

| Pelletizing | Wood pelleting mill machine |

| Cooling | Cooler |

| Packing of Wood Pellets | Packer |

According to the process of wood pellet production, we can see the small wood pelleting plant needs a series of equipment. But, the process can be customized, so is the equipment construction. We offer the service of designing your wood pelleting process and machinery based on your actual condition and your requirements.

If you have plans of making wood pellets or have any idea of investing in the wood pelleting machine industry, you can contact us for information, we are always here for you!

Video of Small Wood Pelleting Machine Running

Here is a video from one of our wood pellet plant projects. From this video, you can see how the wood pelleting machine works. If you have any questions about processing wood pellet fuel, please contact us now!

Small Flat Die Wood Pellet Mill for Small Wood Pellet Production Business Plan

Small Wood Pelleting Press

Wood pelleting machine, also called pellet press, pellet mill, pellet extruder granulator, is a kind of tool which is generally used to process sawdust, straw dust, rice husk, peanut shell, tree branches. Those biomass materials are later solidified into high-density pellet fuel.

Advantages of Small Wood Pellet Mill Machine

Nowadays, wood pellet mills have become a requested equipment all over the world due to the following advantages.

- First, biomass fuel is made up from different woods and materials including rice straw, sawdust, corn straw, wheat straw, rice husk, tree branches, leaves, peanut shell, tree bark etc. these materials are turned into small rod-like solid gradual pieces (pellets) with the help of the machine by crushing, pressing and molding. (Read more: straw pellets for sale>>)

- Second, This flat die pelleting machine is mainly used for small scale pellet production. It produces pellets of uniform moisture content, shape, size and density, which meet the needs of automatic combustion systems for stoves and boilers, and with small storage space and higher combustion value.

- Third, The main aim of using such machines is to provide a new kind of bio-energy which could replace wood, gas, coal and the like widely used in industrial boilers, heating, biomass power, life stoves, plants etc. Biomass industrial boilers are used as the main fuel of the industrial boiler, which solves the problem of environmental pollution. (Learn more: making pellets from leaves >>)

- Finally, with the flat die wood pelleting machine, you can not only make wood pellets in your backyard to meet the daily demand of fuel only if you have suitable raw materials, but also use it to start your small scale wood pellet fuel production factory for getting high return with low cost. Additionally, if you have no idea of where you want to invest in, you can invest in the wood pelleting machine industry.

Note: The result is fuel which is extruded by rollers and ring die under special temperature. (Maybe you are interested in ring die wood pellet machine for medium and large scale pellet mill)

Buy factory price wood pelleting machine from professional manufacturer or supplier--ABC Machinery, learn to process cheap wood pellet fuel, get FREE guidance to setup wood pelleting machine projects for wood pellet business plan in Thailand, United Kingdom, Chile, Russia, New Zealand, Canada etc., at low cost.

Common Questions When Starting Wood Pelleting Production

What are the advantages of heating with pellets?

There are several advantages of heating with pellets instead of using gas, oil, electric heat etc. Pallets are considered as the affordable, clean burning, renewable and available all over the world. They provide with the smell and ambience of burning wood without stacking, cutting, and splitting of cordwood, which makes pellets a more convenient option for homeowners. (Read more: flat die small wood pellet machine for sale)

What are Wood Pallets Made of?

Actually, the pellets used to heat your home are usually made of various materials from woods and wood byproducts such as sawdust. The most common options are: sawdust pellets, straw pellets, efb pellets, coconut shell pellets. As a recycled product, pellets are a great source of environmentally friendly energy for your home. (Related article: biomass pellets cost>>)

Do wood pellets go bad?

ln order to allow your wood pellets serve longer, you should keep them in a dry place away from moisture and humidity. lf they are improperly kept or damaged by water, they can deteriorate and fall apart. So, make sure to prevent it from any kind of humidity.

How can l make sure l have chosen the right pellet type for my home?

So, this is perhaps the most frequently asked question as people generally want to decide whether they have made the right choice or not. Well, first you need to consider the area or the place you are going to heat. This will help you to decide the size of the appliance. Then, you should take into account what venting options are available to you in your current space. Finally, contact your local authorized Harman dealer to get the best answer.

Plan to buy a quality small pelleting press machine to start a mini wood pellet fuel production business? Choose a reliable and experienced wood pellet mill manufacturers and supplier is the very first step. ABC Machinery with years' of experience in the field oil pelletizing equipment is your tursted choice. Don't hesitate to get in touch with us for detailed information about our machines. Tell us you plan and let us help you make the best pellet extruding solution for your company or factory and offer you the most suitable and cost effective wood pellet processing machinery.