ABC Machinery has engaged in the field of feed pellets for many years, which has rich experience. We have won dozens of awards and certifications for powerful technical support and advanced processing equipment. Because of excellent products, considerate services, exquisite craftsmanship, as well as strict inspection and testing, we have gained thousands of projects covered the world. We can not only deliver high quality equipment, but also customize optimal solutions for our customers. Choosing us, you not only have a reliable partner, but also build a solid foundation for your career and wealth. Let us work together to create success in the future.

Characterized by technological innovation and superior performance, our pellet mills are dedicated to providing customers with a unique production experience. In quest for "low consumption and high productivity", we have streamlined our production processes through automation and intelligent technology to achieve optimum productivity. Choose us, you will have excellent machines and maximize benefits. Let's embark on a journey of innovation and success for the pellet from this moment on!

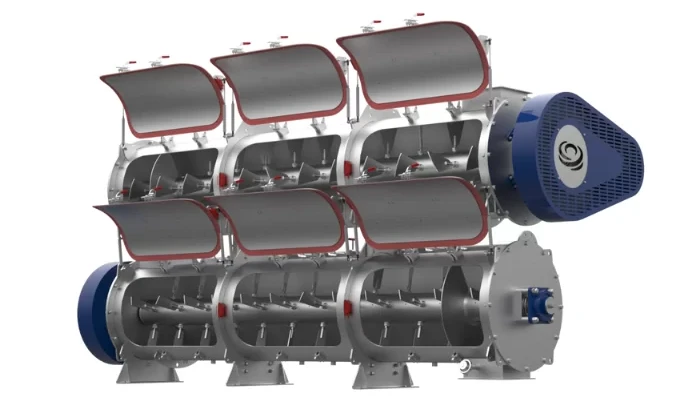

There are multiple places where steam can enter, so that the tempering is sufficient and the degree of maturation is high. Customers can customize as needed, with first, second and third floors to choose from.

They are made of high quality chrome-manganese steel, which is 20 times more wear-resistant than ordinary materials, sturdy and durable, and will not break.

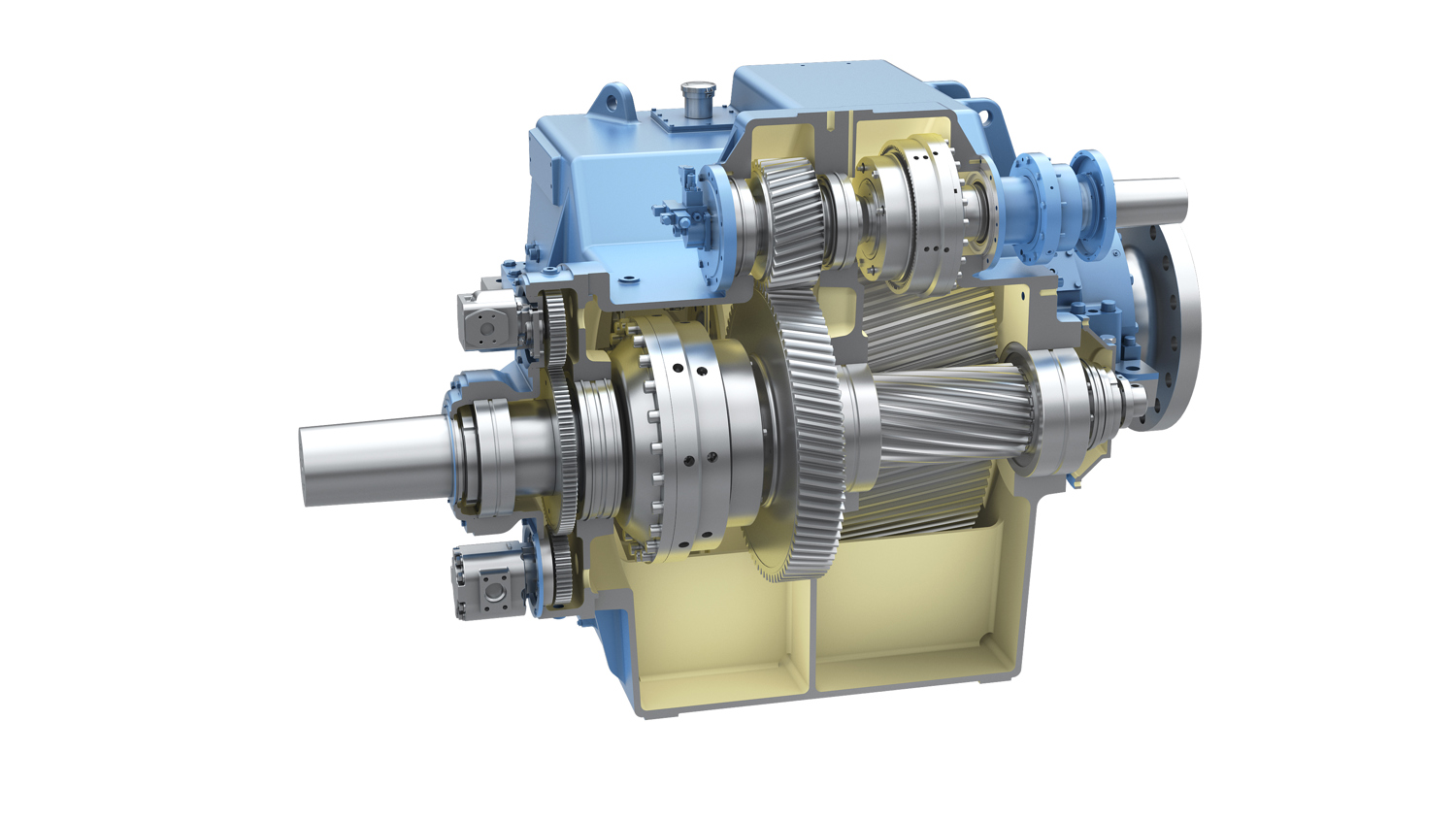

With 3-stage transmission and 1-stage transition gear, its load carrying capacity increases 5-10 times.

From roughage such as pasture and straw to protein feeds such as fishmeal and soya bean meal, the range of raw materials we can handle covers nine categories and more than 100 types. Superior handling capacity achieves high quality feed pellets. Our pellets have the advantages of good moulding, uniformity of particles, good palatability, easy storage and resistance to crushing. Choosing us means 1:1 raw material output with basically zero loss. With our leading technology and high quality machines, choosing us, you'll get high-quality pellets and diversified production programme.

Our services start from eight key dimensions: scale, raw materials, budget, finished products, district, factory, environmental requirements, and market trends. Every aspect will be considered to ensure the most perfect customized solution for you.No matter what type of product you have, no matter how fierce the market competition you face, no matter how unique your needs are, ABC is willing to serve you with professional technology at any time.

Be changed

on your demand.

Matching markets

to local conditions.

Different materials

Different plans!

Each factory

has its unique features.

Best

doesn't have to be most expensive.

Environment&interests

are considered.

Avoiding

unnecessary cost investment.

Long-lasting satisfaction

for market demands.

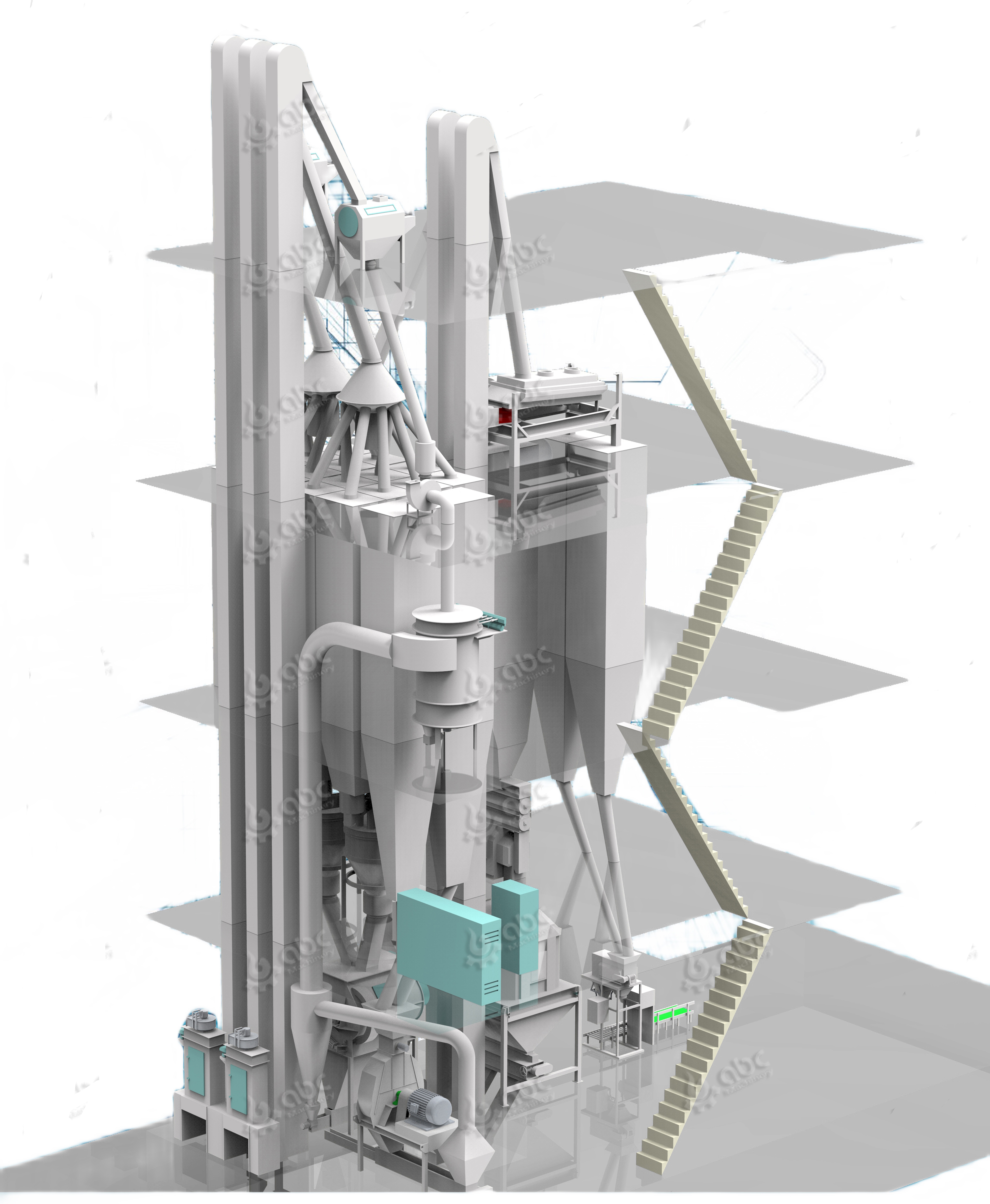

Our projects have all sizes from 1-30T to meet different needs. Our eternal pursuit is providing comprehensive and flexible solutions for our customers to ensure that you have the most suitable equipment and technical support in the filed of feed processing.We move forward all the way, pursuing more excellent production lines, combining customer needs and industry cutting-edge technology, continuously innovating, and looking forward to working with you to discover more excellent possibilities.

Our process design always pursues maximizing efficiency and minimizing costs. From pretreatment, crushing, proportioning to granulation, cooling, screening, every step is efficient and meticulous to ensure the final product of high quality and superior performance.

The raw materials are cleaned and broken to provide suitable conditions for subsequent production for high-quality feed.

The raw material is broken into smaller particles by machine to improve the surface area and adaptability .

Ensure that the various raw materials are mixed in appropriate proportions to meet the nutritional requirements of animals.

Process raw materials into pellets of homogeneous particles to improve the physical properties of the feed and enhance palatability.

Reduce the temperature of the feed to improve its hardness and disintegration resistance.

Separate raw materials based on particle size to remove impurities and improve particle uniformity

Closed and uniform transportation to avoid particle accumulation,pollution and cross contamination.

Encapsulate the pellets to protect the freshness, integrity and ensure product quality of the feed.

We know the importance of 3D design and apply it to all aspects of product development.

From concept to model, relying on advanced technology and professional teams, we integrate innovation into the details of each design to meet your needs for product specifications, shapes and functions.Intuitive 3D models and animations make ideas into reality. Excellent design skills produce unique machines and provide competitive advantages for projects.

Return on investment is a key factor customize a complete feed projects. We will explore the value of feed processing, presenting you with all aspects of of the economic returns so that you can clearly understand the potential benefits and risks of your investment.

Our team will combine many cases and the latest market trends to provide you with reliable data, ensuring that you get advanced machine and achieve maximum economic benefits. We have profound insights and wise decision-making, welcome to contact us now!

Feed pellet production at a rate of x tons per hour; considering 20 hours of daily operation; taking a device working 300 days per year as an example.

| Item | Total Sum(CNY) |

|---|---|

| Total Investment | 131,719,600 |

| Total Production Cost | 232,566,900 |

| Total Income | 292,040,000 |

| Total Profit | 59,473,100 |

Over the course of a year, we anticipate an astounding profit of 59,473,100 CNY, nearly recovering all investment costs within two years.

BEFORE YOU SEND INQUIRY

Please provide us with project information as much as possible:

Detailed information is greatly helpful for us to give you the best-customized offer/quotation at the soonest time.

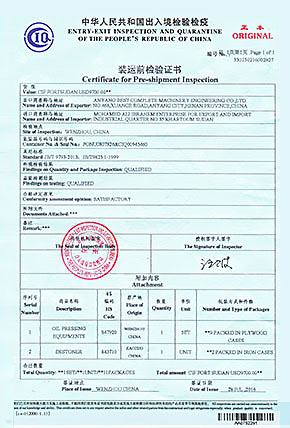

I have opened up all the crates and instolled them. I am very pleased with all the machinery you sent.

I am especially pleased with the pellet mill.. From the packaging crate, the protective wrapping, the spare parts individually wrapped, the tools, and the appearance of the mill... everyhing...t is how I would olways like to recieve merchandise.

-Tim Kamarianakis from Greece